Stainless steel cutting machine Advantages For stainless steel:

Fairly Uniform Edges: The Stainless steel cutting machine cutting edges resulting from using plasma cutters feature, few burrs allowing less secondary processes.

Fast Execution: In comparison to manual cutting methods, plasma cutting is relatively faster allowing quick turn arounds.

High Accuracy: The Stainless steel cutting machine cutting performance of plasma cutter of stainless steel materials of medium thickness is exceptional.

Multiple Usage: Stainless steel cutting machine with Plasma cutting is not just effective for stainless steel metal but other conductive and non-ferrous materials.

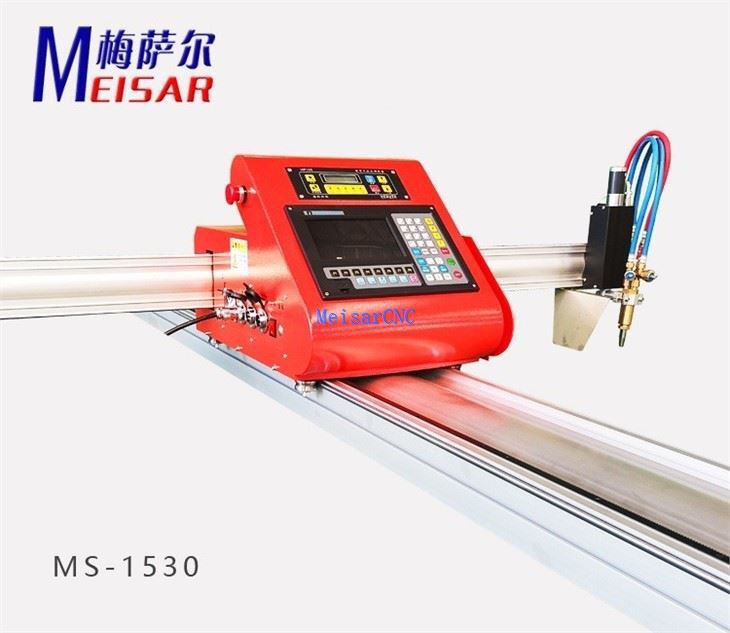

Stainless steel cutting machine simple introduction:

Machine type: Portable type

Control way: CNC control

Cutting way: Plasma

Cutting thickness: 0.1-25mm(recommended), or depends on adopted plasma generator.

Cutting material: mild steel, stainless steel, copper, aluminium, zinc etc.

Cutting area: 1.5x3.0m or customized

Cutting shape type: from CNC system or CAD / CAM software

Stainless steel cutting machine specification:

|

Machine Type |

PLASMA AND FLAME CUTTING BOTH |

CNC PLASMA CUTTING ONLY |

|

Machine Model |

1530HD |

1530D |

|

Torch height controller |

With Plasma THC and Flame Elctric |

With Plasma THC |

|

Effective Cutting Range (X*Y) |

1500*3000mm or customized |

1500*3000mm or customized |

|

Y axis Track Size |

3500mm |

3500mm |

|

Input Power |

Single Phase AC 110 or 220V |

|

|

Approximately 220W |

||

|

Transmission Style |

Rack And Gear |

|

|

Motor Style |

Step Motors Single Drive or Change to be Servo |

|

|

Cutting Speed |

0 - 6500 mm / min (Maximum 6500mm/min) |

|

|

Torch Lifting Distance (Z) |

≤230mm |

|

|

Operation Precision |

± 0.2 mm / meter |

|

|

Flame (Gas) Cutting Thickness |

Piercing Capacity: 5 - 60 mm Edge Start: 5 -120mm |

|

|

Plasma Cutting Thickness |

Depends on the cutting capacity of the Plasma Generator |

|

|

Color Selection |

Red, Yellow or blue |

|

|

Cutting Table |

We offer free table drawing for user, freely to make. |

|

Why does not use flame cutting to cut stainless steel?

Flame cutting is actually the metal burning using high-pressure oxygen flow to blow off the metal cutting, and stainless steel melting point is high, thermal conductivity is not good, stainless steel is not easy to burn, in the flame cutting stainless steel under the influence of preheating flame temperature, on the surface of stainless steel there is a very thin oxide film, that is, high melting point, viscosity of chromium trioxide covered on the surface of stainless steel, Prevents the next layer of metal from burning, so it can not cut normally.

Hot Tags: stainless steel cutting machine, China stainless steel cutting machine manufacturers, suppliers, factory, Hypertherm Plasma Source Type CNC Plasma Cutting Machine, , Portable Plasma Cnc Cutting Cut Thin Metal Sheet, Portable CNC Cutting Machine, Portable Cnc Plasma Cutters, Portable Cutting Machine