Common metal cutting methods

Common metal cutting methods are: grinding wheel cutting, saw cutting, flame cutting, plasma cutting, laser cutting, and waterjet cutting.

Grinding wheel cutting

Metal is cut with a grinding wheel that rotates at high speed. It is a relatively common cutting method. The grinding wheel cutting machine is lightweight, flexible, simple and convenient, and is widely used in various occasions, especially on construction sites and interior decoration. It is mainly used to cut off some small diameter square pipes, round pipes, special-shaped pipes, etc.

Saw cutting

The method of dividing a workpiece or material by cutting it out of a slot with a saw blade is called sawing. The sawing is carried out by means of a metal band sawing machine. Cutting up the material is the most basic requirement of metal processing, so sawing machines are the standard in the machining industry. The process of using the sawing machine needs to select the appropriate saw blade according to the hardness of the material and adjust the optimal sawing speed.

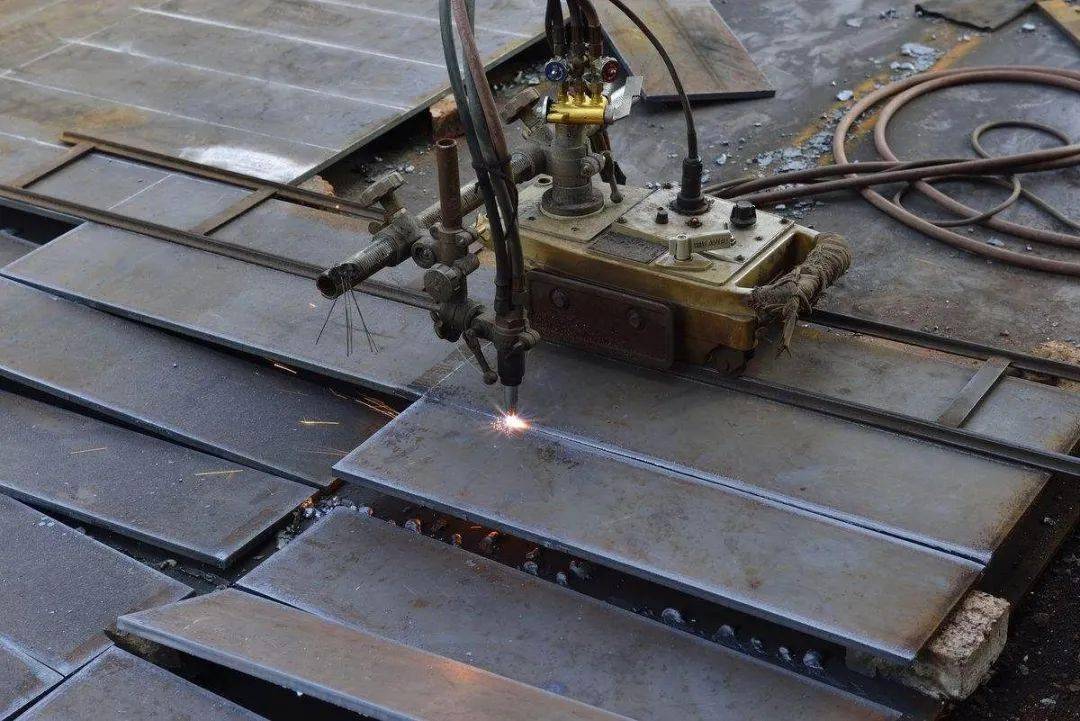

Flame cutting (gas cutting)

The process of flame cutting is to heat the metal through a chemical reaction created by oxygen and red-hot steel, and to soften it and finally melt it. Acetylene or natural gas is used for heating gas.

Flame cutting can only cut carbon plates, and is not suitable for other types of metals, such as stainless steel or copper and aluminum.

The advantage of flame cutting is that it is low cost and can be cut up to two meters thick. The disadvantage is that the heat affected zone and thermal deformation are relatively large, and the section is rough and there are many slag hangings. Considering the subsequent processing, more margin should be placed.

Plasma cutting

Plasma cutting method was invented in the 50s of the 20th century, which is a processing method that uses the heat of high-temperature plasma arc to partially melt (and evaporate) the metal at the incision of the workpiece, and uses the momentum of high-speed plasma to remove the molten metal to form a cut.

Plasma is generally used to cut materials with a thickness of less than 100mm. Different from flame cutting, plasma cutting speed is fast, especially when cutting ordinary carbon steel sheets, the speed can reach 5~6 times that of oxygen cutting method, and the cutting surface is smooth, the thermal deformation is small, and the heat affected zone is less. Plasma cutting is not limited to cutting carbon plates, stainless steel, copper and aluminum and nickel-titanium metals.

Laser cutting

Laser cutting is the use of high-energy laser beams to heat, partially melt, vaporize metal, and complete the cutting of materials, usually used for efficient precision cutting of thin steel plates (<30mm).

The cutting quality of the laser is very good, not only the cutting speed is fast, the dimensional accuracy is also very high (up to ±0.05mm), and because the laser beam acts on a very small area, the heat-affected zone is very small, and the workpiece is almost not deformed.

In terms of cutting quality, laser is superior to plasma; In terms of cutting speed, plasma is faster than laser.

Waterjet cutting

Waterjet cutting is a processing method that uses high-pressure water jets to cut metal. With the continuous improvement of technology, garnet, emery and other abrasives are also mixed in high-pressure water to assist cutting, so as to increase the cutting speed and cutting thickness (up to 200mm). The accuracy of waterjet cutting can reach ±0.4mm or higher.

Waterjets can cut any material with any curve in one go. Because the medium is water, the biggest advantage of the waterjet is that the heat generated during cutting will be immediately carried away by the high-speed flowing water jet, and there is no thermal effect, so it is no problem to use it to cut shells.

Compared to alternatives like waterjet and laser cutting, plasma cutting-and particularly CNC plasma cutting-is highly affordable. The same goes for CNC flame cutting. Gone are the days when budget constraints meant settling for inefficient cutting solutions. Today, both CNC plasma and CNC flame cutting machines offer excellent cut quality at a fraction of the cost, delivering results comparable to more expensive cutting methods.

Here sample for portable type CNC plasma and flame cutting machine MS-P by Hubei Meisar CNC, it is one of the most classical and economical flame and plasma cnc cutting machine.It provide you small and medium metal fabrication shops with the most economical CNC profile cutting machine.

Portable type CNC plasma and flame cutting machine MS-P advanced Structure

- Launched with economical and convenient advantages, one set price below USD1500, weight no more than 130Kg.

- Enjoys broader cutting range of 1.5*3.0m.

- Thick plate cutting upto 120mm and high applicability for kinds of metal materials of carbon steel, alloy etc and metal cutting companies.

- High-intensity, labor-saving, one machine can do jobs same with 5 workers.

- Space-saving, occupy limited space; easy move to new place.

Portable type CNC plasma and flame cutting machine MS-P Product features:

The machine tool and beam are crafted from high-quality aluminum alloy, making them durable, resistant to deformation, and economical. After undergoing stress-relieving treatment and surface oxidation, they provide a long-lasting and refined finish.

- Tailored Track

Offers zero-noise operation with high intensity, speed, and precision.

- User-Friendly Interface

The human-computer interface is designed for ease of use, offering comprehensive functionality that is easy to learn and operate.

- Versatile Cutting Capabilities

The machine supports both portable CNC cutting, capable of cutting carbon steel, stainless steel, and non-ferrous metals.

- CAD Compatibility

Converts CAD designs into program files that can be transferred via USB, enabling plate cutting into any desired shape.

- Dual Cutting Modes

Equipped with both flame cutting and plasma cutting options.

- Automatic Power Recovery

The machine can automatically memorize settings and restore operation after a power outage.

- Torch Height Control (THC)

Automatically adjusts the torch height based on plate variations, protecting the torch and prolonging nozzle life.

- Status Indication Device

Allows for easy monitoring of the machine's operational status.

- Enhanced Protection Features

Includes a positioning system with protection covers, proximity switches, and dual-speed functionality.

- Plasma Compatibility

Compatible with both domestic and international plasma brands.

Related RFQ:What is the plasma cutting and oxy fuel cutting difference?

Plasma and or flame cutting cutting way Guide:

1.Flame cutting:Suitable for cutting carbon steel, thickness more than 20mm.

2.Plasma cutting:Suitable for cutting carbon steel within 20mm,Stainless steel,aluminum or galvanized sheet etc materials; and plasma cutting cost is 1/3~1/2 of flame cutting.

Why select Meisar CNC?

High End!Professional!Create 100 Times Value for You!

Portable type CNC plasma and flame cutting machine MS-P specification:

|

Name |

PORTABLE CNC PLASMA AND FLAME CUTTING MACHINE |

|||

|

Model |

1525HD |

1530HD |

1560HD |

2040HD |

|

Plasma THC |

With Plasma THC |

|||

|

Effective Cutting Range |

1500*2500mm |

1500*3000mm |

1500*6000mm |

2000*4000mm |

|

Customizing |

Track length (effective cutting length Y axis) can be extended as special length |

|||

|

Y axis Track Size (mm) |

2500*273*65 |

3000*273*65 |

6000*273*65 |

4000*273*65 |

|

Input Power |

Single Phase AC 110 or 220V |

|||

|

Approximately 220W |

||||

|

Cutting Modes |

Plasma Cutting (Working with plasma generator) and Flame Cutting |

|||

|

Transmission Style |

Rack And Gear |

|||

|

Motor Style |

Step Motors Single Drive |

|||

|

Cutting Speed |

0 - 6500 mm / min (Maximum 6500mm/min) |

|||

|

Torch Lifting Distance (Z) |

≤105mm |

|||

|

Operation Precision |

± 0.2 mm / meter |

|||

|

Plasma Cutting Thickness |

Depends on the cutting capacity of the Plasma Generator |

|||

|

Cutting Table |

We offer free table drawing for user, freely to make. |

|||

Hot Tags: metal cnc cutter, China metal cnc cutter manufacturers, suppliers, factory, Portable Cnc Plasma Flame Cutting Machine, Honey Bee CNC Plasma Flame Cutting Machine, crossbow cnc, Gas Cnc Cutting, Plasma Cnc Cutting, Automat Cutting Machine