Gantry Fiber Laser CNC Cutting Machine (12000W Fiber laser--30000W fiber laser CNC cutting machine) MS-LG

Gantry Fiber Laser CNC Cutting Machine is designed and manufactured by Hubei Meisar CNC Technology Co., Ltd. according to rich machinery design experiences and wide market research. This machine can accurately process and cut the materials as follows: carbon steel, square pipe, round pipe, and other metal materials. This is the best cutting solution for the replacement of high-definition plasma cutting.

Gantry Fiber Laser CNC Cutting Machine MS-LG feature:

The gantry cutting machine has no contact with the workpiece and will not scratch the surface of the workpiece when working. The cutting speed is fast, the incision is smooth and flat, and there is generally no need for follow-up processing. The cutting heat-affected zone is small, and the plate deformation is small. The incision is free of mechanical stress and shear burrs. High processing accuracy, good repeatability, no damage to the surface of the material; CNC programming can process arbitrary floor plans, and large widths of the whole board can be cut without opening the mold, which is economical and time-saving. Generally, our Gantry Fiber Laser CNC Cutting Machine MS-LG has the following advantages:

1. High efficiency

Due to the transmission characteristics of the laser, the gantry laser cutting machine has a lot of CNC workbenches, and the whole cutting process can be completely numerically controlled. When operating, you only need to change the CNC program; it can be applied to cutting parts of different shapes.

2. Fast

The cutting speed of the gantry cutting machine can reach 25000 mm/min. During the cutting process of the gantry cutter, there is no need to clamp and fix the material.

3. The cutting quality is very good.

The cutting machine has a narrow incision, the two sides of the slit are parallel to the surface, the dimensional accuracy of the cutting parts can reach 0.05 mm, the cutting surface is smooth and beautiful, and the surface roughness is only tens of microns. No machining is required, and the parts can be used directly. The material passes through a gantry laser cutter with a small width of the heat-affected zone, and the properties of the material near the slit are hardly affected.

Gantry Fiber Laser CNC Cutting Machine (12000W Fiber laser--30000W fiber laser CNC cutting machine MS-LG) configuration:

|

Configuration |

Gantry Series |

|

Servo |

Japan Panasonic 2.9kw*2+1.5KW*1+0.4kw*1 |

|

System |

FSCUT12000- FSCUT20000 |

|

Gear reducer |

SHIMPO |

|

Linear Guideways |

HIWIN45-25 |

|

Electrical control cabinet |

Independent Electrical control cabinet |

|

Laser source |

12000-20000 Raycus /MAX Or |

|

Rack |

APEX6 |

|

The beam |

Heavy duty solid casting |

|

Machine bed |

Casting machine bed |

Gantry Fiber Laser CNC Cutting Machine Specification:

Cutting width range: 2.0m-10.0m

Cutting length range:6m-30.0m

Laser source: 12000w-20000W (12000w-30000W)

Cutting Thickness: Mild Steel ≤50mm,Stainless Steel≤25mm

Running Speed(Max): 25000mm/min

Gantry Fiber Laser CNC Cutting Machine Platform:

* It adopts air exhausting.

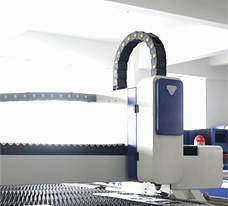

* With the Third Generation steel gantry, which is manufactured with aerospace standards and formed by 4300 tons of press extrusion molding, after aging treatment, its strength can reach 6061 T6, which is the strongest strength of all gantries, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

* The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes.

* Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed; it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

* High strength, stability, and tensile strength, ensuring 20 years of use without distortion;

* Thickness of rectangular pipe wall is 10 mm and weights 4500 kg.

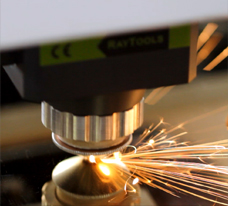

* Laser cutting head; it can focus automatically. Without manual focusing, the software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thicknesses.

* The speed of automatically adjusting the focus lens is ten times that of manual adjusting.

* Bigger adjustment range, Adjustment range -10 mm~ +10 mm, precision 0.01 mm, suitable for 0 ~ 20 mm different types of plates.

* Long service life, Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

* The Hubei Meisar CNC fiber laser cutting machine is equipped with a German Atlanta rack, a Japanese Yaskawa motor, and a German Neugart reducer.

* The positioning accuracy of the machine tool can be 0.02 mm, and the cutting acceleration is 1.5 g. Working life is up to 10 years.

Gantry Fiber Laser CNC Cutting Machine QUALITY MANAGEMENT SYSTEM

Hubei Meisar CNC is one of the biggest suppliers among cutting equipment in Mid China. Company mainly engage in CNC laser cutting machine, CNC plasma cutting machine, CNC Pipe/Tube cutting machine, etc. Meisar CNC has 14 years history, serving more than 80 countries and regions.

Meisar CNC has strict quality control system and quality management team. Strictly adhere to the general standards of the industry and company guidelines. Implement quality monitoring from every aspect of R&D, production and after-sales of laser equipment, to ensure that each device can meet customer's requirements.

Gantry Fiber Laser CNC Cutting Machine Incoming Inspection

For every part of the machine, Meisar CNC is strictly control the quality.

Not only require suppliers to provide quality inspection reports, but also strict quality monitoring will be carried out when the parts are in the factory.

|

Laser Source Test |

Laser Head Test |

Square Track Detection |

Rack Detection |

Motor / Reducer Testing |

|

|

|

|

|

|

The width, repetition frequency and peak power of the laser pulse are detected by using the photoelectric detectors and oscilloscope. |

Stability test and aging test for laser head. |

Testing the flatness and straightness of the track to ensure that the machine runs smoothly. |

The precision and consistency between gear and rack are mainly tested |

We will adjust the suitability of the machine through continuous empty experiments. |

Gantry Fiber Laser CNC Cutting Machine MS-LG Process Control

The assembly process of the machine will also affect the customer's feeling when using the machine, Therefore, in the process of machine assembly, Meisar CNC from the most basic machine bed to the final assembly of the whole machine is strictly followed by the quality management standard.

|

Machine Bed Welding |

Gantry Milling |

Guide Rack Mounting |

Other Hardware Parts Installation |

|

|

|

|

|

The bed frame is welding by 10mm thick and high strength square. |

Meisar CNC has its own gantry milling. |

The straightness of guide rack is guaranteed by using laser collimator |

we install the motor reducer strictly according to standard production process and standard |

Gantry Fiber Laser CNC Cutting Machine MS-LG Pre-delivery Inspection

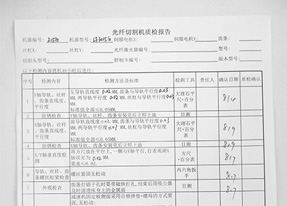

The machine will accept a number of quality testing, respectively, from the performance, stability, fit, practical and other aspects of consideration, for non-compliance with the standard part of the arrangements for debugging and maintenance, To ensure that the final factory, the machine is in the best condition.

|

Inspection Report |

The Whole Machine Is Fitted With a Load-Free Test |

Material Shearing Test |

Machine packing |

|

|

|

|

|

Every component of the machine, every performance, every parameter is carefully tested. |

Ensure the cutting accuracy through laser interferometer checking and 24 hours testing, And make sure the machine will be in the best condition. |

Before delivery, different metal materials will be cut, observe the cutting effect, and then adjustment according to the need |

The laser equipment requires multiple protective measures during the packing process to ensure that each component is not affected by the collision |

Hot Tags: gantry fiber laser cnc cutting machine, China gantry fiber laser cnc cutting machine manufacturers, suppliers, factory, Cnc Portable Cutting Machine, Cnc Profile Cutter, hypertherm plasma cutter, Cnc Laser Cutting Machine, Gantry Cnc Flame Cutting Machine